Large-size sheet metal laser cutting machine FIBER Master 3D

The power of large format. Laser precision

Dynamics, precision and safety – meet STIGAL’s new line of laser cutting machines

Tailor-made for large-scale challenges - such a large work table allows cutting extremely long sheets and parts in a single cycle. Minimized handling and optimized part layout translates into higher productivity and lower production costs.

High power, European standards and reliability. Raycus fiber-optic source with PLD system ensures fast cutting of thick materials with the highest precision and beam stability - even in long-term operation.

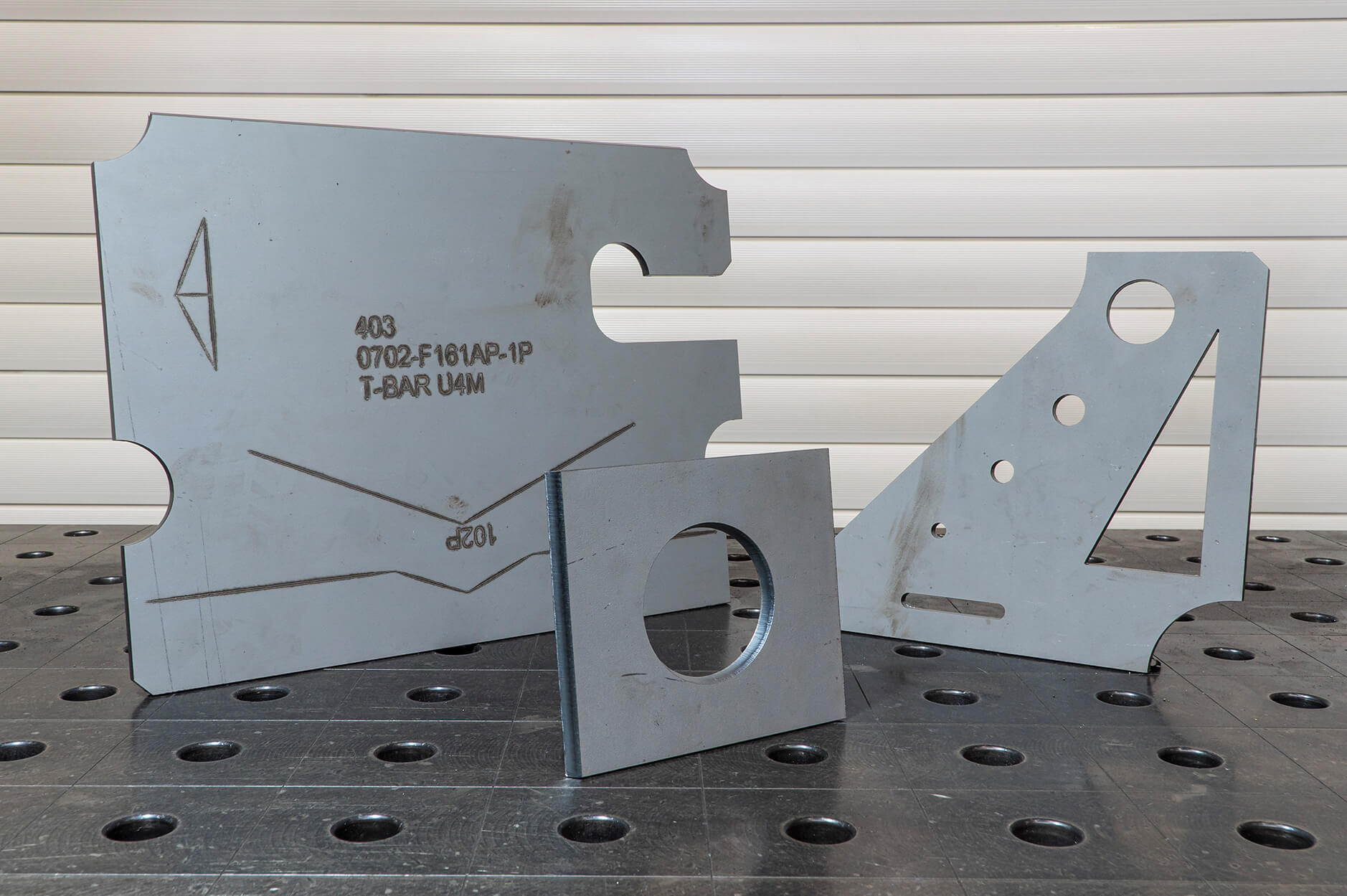

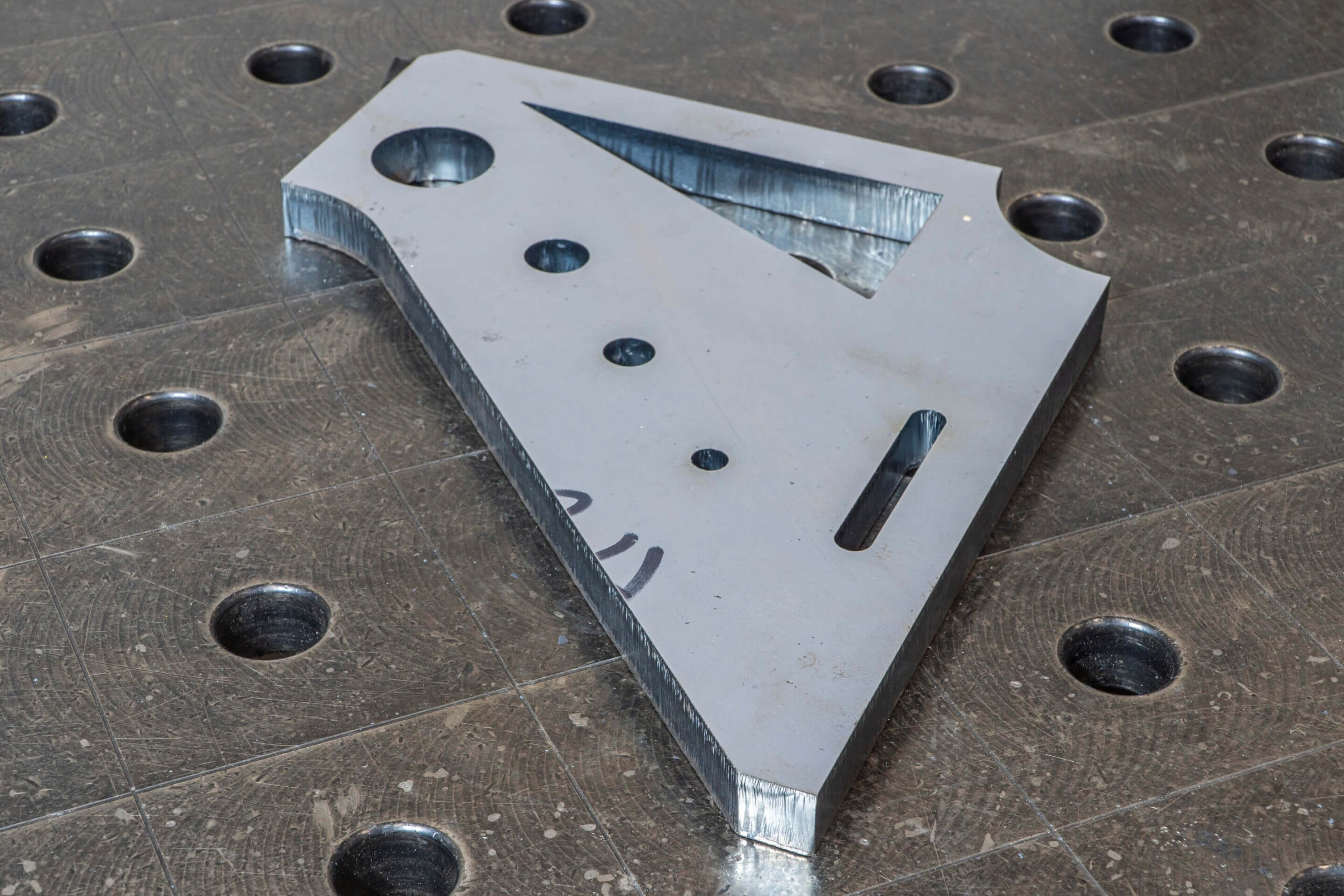

Simultaneous cutting and edge preparation for welding in a single pass. 3D head with ±45° range eliminates the need for additional machining, reducing production time and improving the quality of welded joints.

The mobile safety guard used in the system moves with the portal over the work table, covering the cutting zone. It thus creates a local, sliding safety chamber that effectively limits the spread of radiation outside the work area.

Solutions that optimize production time and costs

STIGAL machines are distinguished by precision cutting, the ability to perform chamfers and bevels, and automatic maintenance of operating parameters. Innovative 3D heads and advanced control systems allow the realization of complex projects, ensuring high quality parts and reliable operation even in the most demanding production tasks. Intuitive operation makes it easy to implement operators, and robust construction guarantees a long service life of the equipment. In this way, STIGAL supports the development of modern industrial plants.

3D cutting head with beveling function

The machine is equipped with a modern multi-axis 3D cutting head, which, in addition to movements in the X, Y, Z axes, has the ability to tilt the tool at a given angle (2 rotary axes). Such a design of the head allows cutting at an angle of up to ±45° with respect to the vertical, which makes it possible to perform the required chamfers and bevels on the edges of the cut parts.

Thanks to the 3D head, this process takes place during the actual cutting process, eliminating the need for subsequent edge processing (e.g., tedious chamfer grinding on cut parts). Single-step cutting of the part’s edge along with the chamfer significantly increases production efficiency, ensuring accurate, repeatable preparation of the part for welding.

The head is equipped with an automatic system for maintaining height and focus relative to the material, which also works in angle cutting mode. An advanced system of capacitive measurement of the distance from the surface of the sheet metal and CNC control compensates for deviations in the head’s path so that even in bevel cutting, the focal distance from the material remains constant. As a result, beveled edges are even and clean along the entire length of the cut, and the bevel angle exactly matches the design intent. The quality and precision of the bevels made has a direct impact on the quality and cost of welding – an even, smooth chamfer ensures better weld adhesion and full fusion, which improves the strength of the joint and reduces the consumption of welding material

Raycus laser source

At the heart of the system is a high-performance fiber laser source of up to 30 kW from Raycus for the European market. This laser is characterized by very high power and beam quality, which enables efficient cutting of thick materials at high speeds. The 30,000-watt power allows for long-lasting, stable cutting of steel sheets with high precision.

The Raycus HP-series laser complies with safety standards, with CE and PLD (Performance Level D) in force in Europe. The source is equipped with an advanced Photonic Light Delivery system, which takes care of the stability and safety of the process. In practice, this means extensive beam monitoring and control mechanisms: the laser has sensors monitoring, among other things, the level of reflected and leaked light, as well as internal power redundancy, which allows the output to remain stable even during long cutting runs.

Work safety and laser shielding

STIGAL has consistently focused on operator safety and the highest standards of protection in industrial environments for years. Our machines are designed with the strict safety standards of the European Union in mind, protecting users both from direct exposure to laser radiation and from secondary reflections from the material.

The mobile protective shield used in the system moves with the portal over the work table, tightly surrounding the cutting zone. It thus creates a local, sliding safety chamber that effectively limits the spread of radiation outside the work area.

Such a solution provides a level of protection comparable to that of a full cab, while at the same time allowing free processing of long and unusual parts. Operators can work in a comfortable and safe environment while maintaining full control over the cutting process.

Check out the detailed data and compliance of FIBER Master 3D with the most important industry standards

| Width |

|

|---|---|

| Length |

|

| Laser cutting |

|

| Positioning accuracy: |

|

| Cutting accuracy |

|

| Drive system |

|

|---|---|

| Running gear |

Linear guides, built with two steel and hardened shafts (62-64 HRC). Completely greaseless system in the X axis, resistant to industrial conditions. Downward-facing toothed bar - resistant to dust generated during cutting. Y- and Z-axis based on linear guides with profile rail. |

| Material table |

Extraction table with intelligent section control system (ECTS). Method of foundation: |

| Data transmission |

|

| Code format |

|

| Electromagnetic compatibility directive |

|

|---|---|

| Machinery directive |

|

| Safety of thermal cutting machines |

|

| Machine safety - general principles of design |

|

| Machine safety - electrical equipment of machines |

|

| Machine safety - guards |

|

| Numerical control of machines |

|

| Thermal cutting |

|

| Acceptance tests of oxygen cutting machines - mapping accuracy |

|

STIGAL technology in practice - sample testimonials

STIGAL machines are distinguished by precision cutting, the ability to perform chamfers and bevels, and automatic maintenance of operating parameters. Innovative 3D heads and advanced control systems allow the realization of complex projects, ensuring high quality parts and reliable operation even in the most demanding production tasks. Intuitive operation makes it easy to implement operators, and robust construction guarantees a long service life of the equipment. In this way, STIGAL supports the development of modern industrial plants.

Explore configuration and accessory options

Each machine in our offer is fully customizable – you can choose additional modules and accessories that best suit the specifics of your production. Check out the available accessories and create a solution perfectly tailored to your requirements.

Full control over production and convenience of operation

State-of-the-art control software ensures full control over the cutting process, optimization of production, and convenience and safety of operation – regardless of the operator’s level of expertise.

The FSCUT control system is a state-of-the-art solution dedicated to controlling CNC laser cutters. It features an intuitive user interface that allows quick programming and optimization of cutting processes. The system provides precise control of motion trajectories and automatic path optimization, resulting in high cutting quality and material savings. FSCUT supports a wide range of file formats and integrates with various industrial automation components. With extensive diagnostic functions and remote support, it guarantees reliability and ease of use for both operators and service.

The large and intuitive touch panel, SmartCut intelligent assistant and quick access to instructions and tables make the machine easy to operate even for new operators, and make daily work comfortable and safe.

Versatile application in various industrial sectors

STIGAL’s solutions work well in a wide range of industries – from machinery manufacturing and steel structures, to marine and energy, to automotive and logistics. Our equipment enables precise cutting, preparation of parts for welding and implementation of custom projects. With flexible configurations and high performance, STIGAL machines support both series production and individual orders in the most demanding environments.

Manufacturing of halls, canopies, support columns, balustrade components and steel stairs – wherever steel profiles and tubes are used. Fiber Master 3D allows quick and precise preparation of components for welding and assembly.

Advanced capabilities for cutting tubes and profiles at angles, cutting holes and preparing pipe nodes make Fiber Master 3D applicable to shipbuilding, oil rigs and offshore installations.

The machine is ideal for prefabrication of process pipelines, support structures, housings for heat exchangers or elements of transmission installations – wherever precision and repeatability count.

Knowledge and inspiration for modern manufacturing

See more inspiration, tips and news related to cutting technology and manufacturing automation. Check out what else can improve your company’s workflow.

We will help you choose the software for your machine

Contact our technical advisor and we will select the ideal tool for your machinery and cutting processes.